Micromaterials with tunnels for lighter and smaller batteries

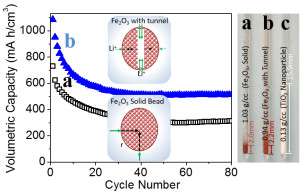

Fig. 1. (Left) Volumetric capacity and cycling performance of (a) Fe2O3 solid microbead, and (b) Fe2O3 chevron microbeads with tunnels. (Right) Comparison of tapped density of (a) solid microbead and (b) chevron microbead of α-Fe2O3, (c) commercial TiO2 nanoparticles (AEROXIDE, P25), respectively.

Ideally, the next-generation lithium-ion batteries should be lighter or can store more energy per mass and smaller or store energy per volume. Nanomaterials have been proposed to store a large amount of energy. However, nanomaterials have an extremely low volumetric density. To illustrate, graphite has a volumetric density of 2.6 g/cm3; in contrast, the popularly studied graphene powder has a volumetric density about 0.1 g/cm3. Therefore, nanomaterials based electrodes may increase the specific energy (energy per mass) but not the volumetric energy (energy per volume) of lithium-ion batteries. We are working on to improve both specific energy and volumetric energy, focusing on micromaterials instead of nanomaterials. However, micromaterials are not as effective as nanomaterials in reversible lithium storage due to their large size.

Fig. 2. 3D illustration vied from different perspectives and FESEM images of (a) Fe2O3 solid microbead, and (b) Fe2O3 chevron microbeads with tunnels.

We tried to tunnel holes in micromaterials to store more energy. We designed and demonstrated the preparation of unique chevron-like microbeads of α-Fe2O3. The unique structure can facilitate the diffusion and migration of both electrolyte and Li ions. Our results suggested that the micromaterials with tunneled holes can store 50% more energies/electrons per volume than solid micromaterials without holes.

Our on-going efforts are to further optimize the electrochemical performances of the materials. We believe that micromaterials should attract the deserved attention as those nanomaterials for

rechargeable batteries.

Publication

Tunneling holes in microparticles to facilitate the transport of lithium ions for high volumetric density batteries.

Zhu J, Ng KY, Deng D.

Nanoscale. 2015 Aug 20

Leave a Reply

You must be logged in to post a comment.